Fiber reinforced polymers in architectural design

Fabrication processes of FRP elements vary according to the type of industry and the characteristics of the final element. All conventional fabrication processes for FRP are based on molding. Among the most widely used molding techniques are contact molding, compression molding, vacuum molding, resin injection molding, and even injection molding with prepregs or filament winding, each of which require the use of a certain type of mold. The cost of fabricating an element is directly connected to the chosen molding technique, the scale and the formal complexity of the element/mold.

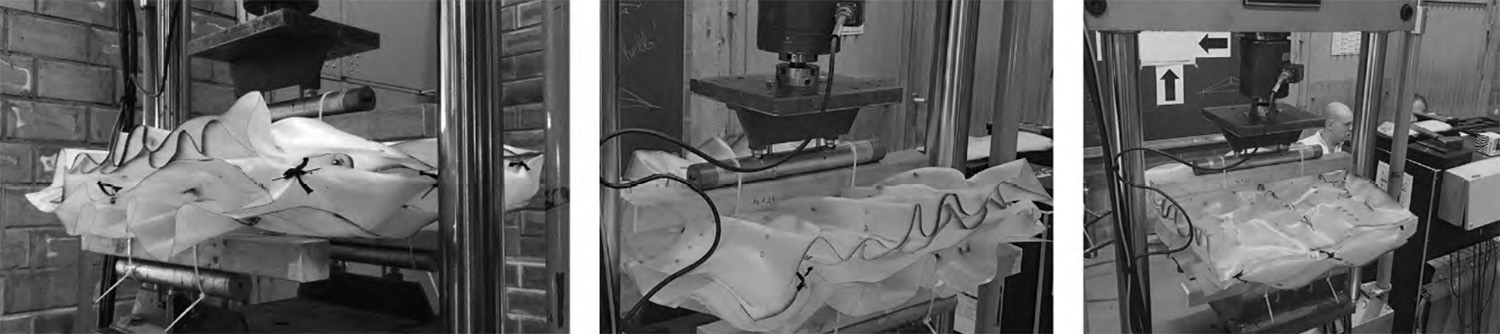

The research addresses the limitations arising from the need for a mould in FRP fabrication when used in architectural applications. IT focuses on the fabric characteristics of the fiber elements in composite FRP and its self-organizational properties. Using ideas from the body of research on form finding in architecture, and learning from fabric formwork methodologies, this study investigates ways to develop a design and fabrication method for the generation and fabrication of complex geometry architectural elements using FRP. Adapting textile attributes and manipulation techniques from the world of garment making, the suggested process seeks for the introduction of surface articulation and complex forms into the fabrication of FRP elements. It suggests the freedom from molds, by treating the FRP as hanging membrane, and proposes ways for local differentiation of the surface for performance, optimization and ornamentation.

The variety of manners by which form is obtained in textile is demonstrated in the garment-making discipline and can be placed under four main categories: the drape, being a fabric's property, pattern-making and fabric manipulations, being tailoring practices and "fully-fashioned", which is a fabric material construction. The term of Fabric Materiality is coined to represent the unique properties of textile materials and their processing techniques, together with the inherent design approaches these introduce. Treating mate- riality as part of a larger design paradigm, Fabric Materiality is an approach to tightly related design and fabrication, originating from mate- rial properties. In this research the general concept of Fabric materiality is developed with regards to fibre composites. Three main characteristics of textiles were identified as defining the essential properties of Fabric Materiality: fabric manipulations, self-organisation and resilience.Fabric manipulation refers to the multitude of parameters that affect the physical properties of the fabric, from the fibre itself to its spatial structuring by weaving, felting, knitting etc.. Self organisation refers to manipulations on an higher level of hierarchy, dealing with the fabric itself. It refers to the ability of fabrics to embrace complex form as a result of their manipulation. This multitude of simple and weak elements that interact and construct a greater whole is a key factor of the fabric's resilient properties. It gives the material its flexibility and ability to recover to an initial or improved state after an event of stress, demonstrating soft stability and robustness.

Fabric Materiality could be embedded in the process of fabrication of FRP, enhancing textile attributes and biologically inspired design methods. Integrating textile-related techniques of form-making and material construction from the world of garment making as well as from the architectural form finding discipline suggests the freedom from moulds, and proposes ways for local differentiation for performance, optimization and ornamentation. Relying on the natural properties of fibre architecture, both at the material level and on the structural level, enables simple the generation of complexity.

Embedding Fabric Materiality in the fabrication and design process of architectural FRP to achieve a complex structure with biological attributes is developed in this research through numerous case studies. Through a case study, the paper examines the potential of developing a resilient FRP structure by employing principles extracted from the biological resilient model of a bird’s nest, relying on the integration of Fabric Materiality. Transposing these principles into a FRP structure faces the challenge of structured randomness at the structure level and crafted variation at the component level. The resulting structure is extremely light, self-supportive and resists lateral loads, is varied and demonstrates resilient properties.

Scientific publications that were published on this research:

Blonder, Arielle. 2015. ‘Full Scale Form Finding: Introducing Fabric Materiality in the Fabrication of Architectural FRP’. In 20th International Conference on Composite Materials. Copenhagen: ICCM.

Blonder, A. Grobman, Y.J. Design and fabrication with fiber-reinforced polymers in architecture: a case for complex geometry. Architectural Science Review, 59:4, 257-268. 2015 DOI: 10.1080/00038628.2015.1020479.

Blonder, A., Grobman, Y.J., Alternative Fabrication Process for Free-Form FRP Architectural Elements Relying on Fabric Materiality Towards Freedom from Molds and Surface Articulation. The next city - new technologies and the future of the built environment [16th International Conference CAAD Futures 201. Sao Paulo, Brazil, July 8-10, 2015, pp. 397-410. (Fully refereed abstract and paper). 2015.

Blonder, A., Grobman, Y.J. “Natural Complexity: Embedded Fabric Materiality in Fibre-Reinforced Polymer Fabrication”. Complexity and Simplicity, the 34th eCAADe annual Conference. Oulu School of Architecture. Finland. August 2016. Pp 581-589. (Fully refereed abstract and paper). 2016

Blonder, Arielle. 2016. ‘A Matter of Resilience’. In LifeObject: Merging Biology & Architecture, 81–85. Sternthal Books.

Blonder, A., Grobman, Y.J. “Crafted variation in FRP: Resilience by fabric materiality”. Spatial Structures in the 21stCentury, the IASS 2016 Annual International Symposium. The University of Tokyo, Japan. September 2016. (Fully refereed paper). 2016

Blonder, Arielle. 2017a. ‘Fabric Materiality FRP: Shifting towards Structures of Bio:Inspired Properties’. In KINE[SIS]TEM’17 From Nature to Architectural Matter, 46–55. Lisbon, Portugal: DINÂMIA’CET : IUL.

Blonder, Arielle. 2017b. ‘Layered Fabric Materiality in Architectural FRP Surface Elements’. In Proceedings of the IASS Annual Symposium 2017 Interfaces: Architecture.Engineering.Science 25–28th September 2017, Hamburg, Germany Annette Bögle, Manfred Grohmann (Eds.). Hamburg, Germany.

Blonder, A., Grobman, Y. J., Latteur, P., Pleated Facades: Layered Fabric Materiality in FRP Surface Elements. International Association for Shell and Spatial Structures (IASS 2018) Annual International Symposium, MIT. July 16-20th. Boston 2018.

Van:Essen, Yael, Ben Bauer, Arielle Blonder, and Noy Lazarovich, eds. 2016. Lifeobject: Merging Biology & Architecture. Sternthal Books