Digital fabrication of complex geometry in architecture: developing theory and rationalization methods for the building scale

Rationalization is widely recognized as an important design strategy in contemporary architectural projects, especially in projects with complex geometries, built using digital fabrication processes.

The research shows that the capabilities of the fabrication machinery used are the most frequently encountered rationalization constraint in realized architectural projects. Additionally, we describe a new taxonomy for rationalization strategies, which incorporates functional information with the temporal information described by traditional classifications. Using this taxonomy, we identify trends within the industry and the academia and point to the growing popularity of parametric co-rationalization approaches.

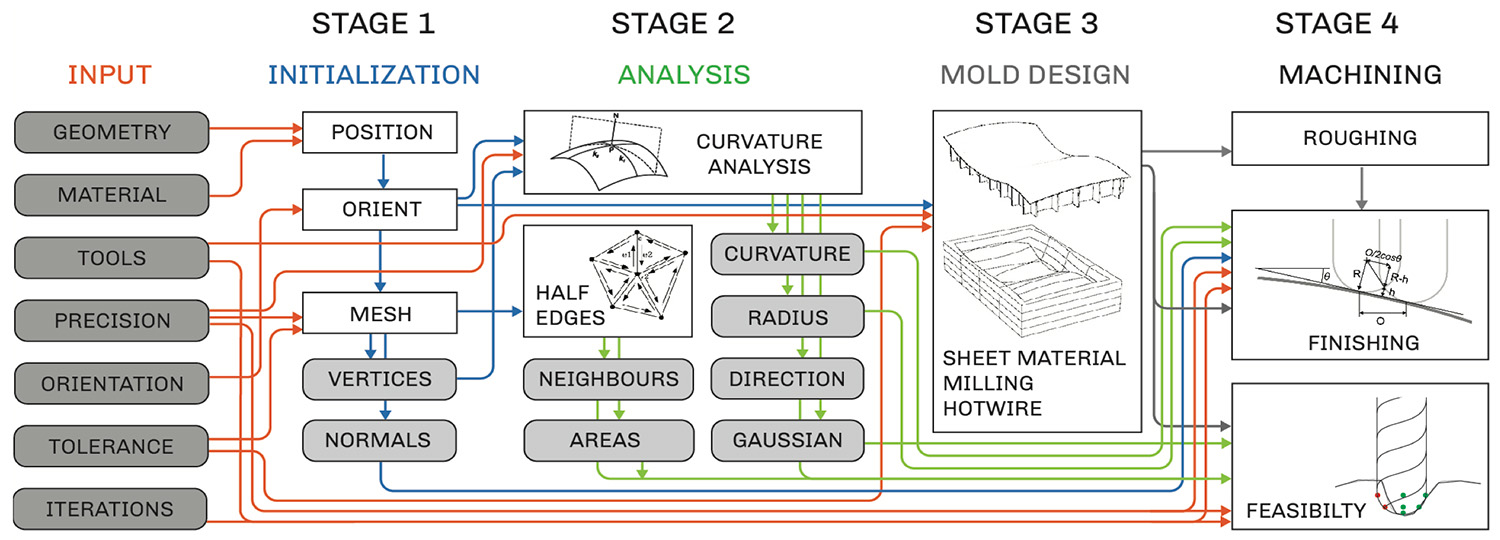

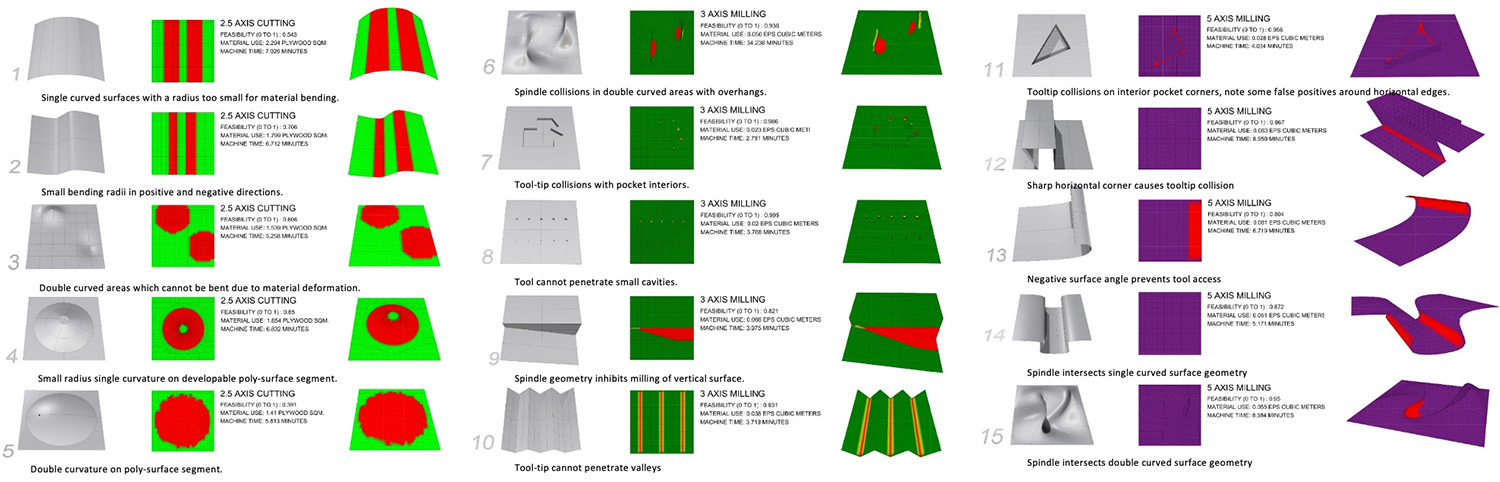

The second part of the research develops a framework for an analysis method and computational tool, which evaluates the fabrication parameters of complex geometries. The suggested method predicts the feasibility, material use, and machining time required for fabricating the moulds for these geometries. It achieves this by interrogating geometric properties instead of traditional machining simulations. Using the algorithms developed in this research, the method can provide real-time evaluation of computer-controlled mould fabrication techniques such as cutting and assembling sheet materials, multi-axis milling of volumetric material, and robotic hot wire cutting.

The method was implemented in a computational tool. It predicts the feasibility, material use and machining time of a geometry in relation to different fabrication techniques. It uses geometric properties to mathematically estimate these parameters without simulating the actual machining. Using the algorithms developed in this research, the method can provide real time evaluation of computer-controlled mould fabrication techniques such as cutting and assembling sheet materials, multi-axis milling of volumetric material, and robotic hot wire cutting. The research demonstrates how the method provides real-time visual feedback for designers and allows them to adjust their design according to fabrication constraints in the early design stages. Using architectural case studies, we show how the analysis results provide precise cost estimates and help minimize fabrication resources in manual or automatic fabrication optimization processes.

Collaboration:

This project was developed in collaboration with prof. Guedi capeluto.

Teaching related to this research:

Computer aided fabrication

Patents:

Austern G., Grobman Y.J., Capeluto I.G., Elber G., Real Time Evaluation Method for the Fabrication Resources of Complex Geometry Molds, 2018. Provisional Patent, EFS ID: 33471961, Application Number: 62719676

Scientific publications that were published on this research:

Austern, G. Capeluto, I.G, Grobman, Y.J., Rationalization Methods in Computer Aided Fabrication: A Critical Review. Automation in Construction journal. 90, 281–293. 2018. DOI: 10.1016/j.autcon.2017.12.027. Received the Technion Jacobs Award for the Best Paper of 2018.

Austern, G. Capeluto, I.G, Grobman, Y.J., Real-time fabrication analysis: a method for evaluating fabrication constraints of complex concrete shapes. Architectural Science Review. 6 August 2022. DOI: 10.1080/00038628.2022.2107992

Austern, G. Capeluto, I.G, Grobman, Y.J., Evaluating the Buildability of Architectural Geometries: Embedding fabrication awareness into the design of concrete elements. International Conference on Architecture and Civil Engineering proceedings (ACE). May 14-15th. Singapore. 2018. DOI: 10.5176/2301-394X_ACE18.38

Austern, G. Capeluto, I.G, Grobman, Y.J., Fabrication Aware Design: A method for rationalizing concrete façade elements. In Kepczynska-Walczak, A, Bialkowski, S (eds.), Computing for a better tomorrow - Proceedings of the 36th eCAADe Conference - Volume 1, Lodz University of Technology, 19-21 September 2018, pp. 727-734, Lodz, Poland. 2018.

Austern, G. Capeluto, I.G, Grobman, Y.J., Adapting architectural form to digital fabrication constraints. In Hesselgren, L., Killian, A., Malek, S., Olsson, K.G., Sorkine-Hornung, O., Williams, C., Eds. Proceedings of the international conference on Advances in Architectural Geometry (AAG). September 24-25th. Chalmers University of Technology in Gothenburg, Sweden. Pp. 10-29. 2018.

Austern, G. Capeluto, I.G, Grobman, Y.J., Fabrication aware design of concrete façade panels to Re/calibration: on imprecision and infidelity. ACADIA Conference. 18-20th October. Universidad Iberoamericana. Mexico City 2018. Pp. 136-145.