3D printing with earth materials

Earthen materials are a composite of earth/clay with straw or other similar biological materials that serve as the fibers/reinforcement. One of the main limitations of using earth as opposed to concrete is its strength. This limitation is usually addressed by adding cement/lime to the mixture, which reduces the environmental benefits of the mixture. This research proposes avoiding the need to add non-recyclable/reusable materials to the mixture by adding mycelium and using its ability to act as fiber and bonding material. Furthermore, mycelium can accelerate the decrease in water due to its high hygroscopicity.

The craft of earth architecture, based on vernacular knowledge using locally available materials, has been evident since 8000 BC. The use of earthen material is advantageous, being 100% reversible and showing potential for passive indoor

climate regulation. Historically, earth-building practices have been based on an open-ended process in which uncertainty and risk are embedded as core precepts. The use of earthen materials in vernacular architecture has recently been given increasing attention. Although digital fabrication has been recognized for its potential environmental benefits, there has been little research on digital fabrication with earthen material.

The research focuses on three main directions:

- Expanding the knowledge on earth material for 3D printing

- Developing a field-based methodology for the material mixture for 3D printing with earth

- Developing new geometries for 3D bricks/elements from the earth with bio-additives such as mycelium

Direction 1-2:

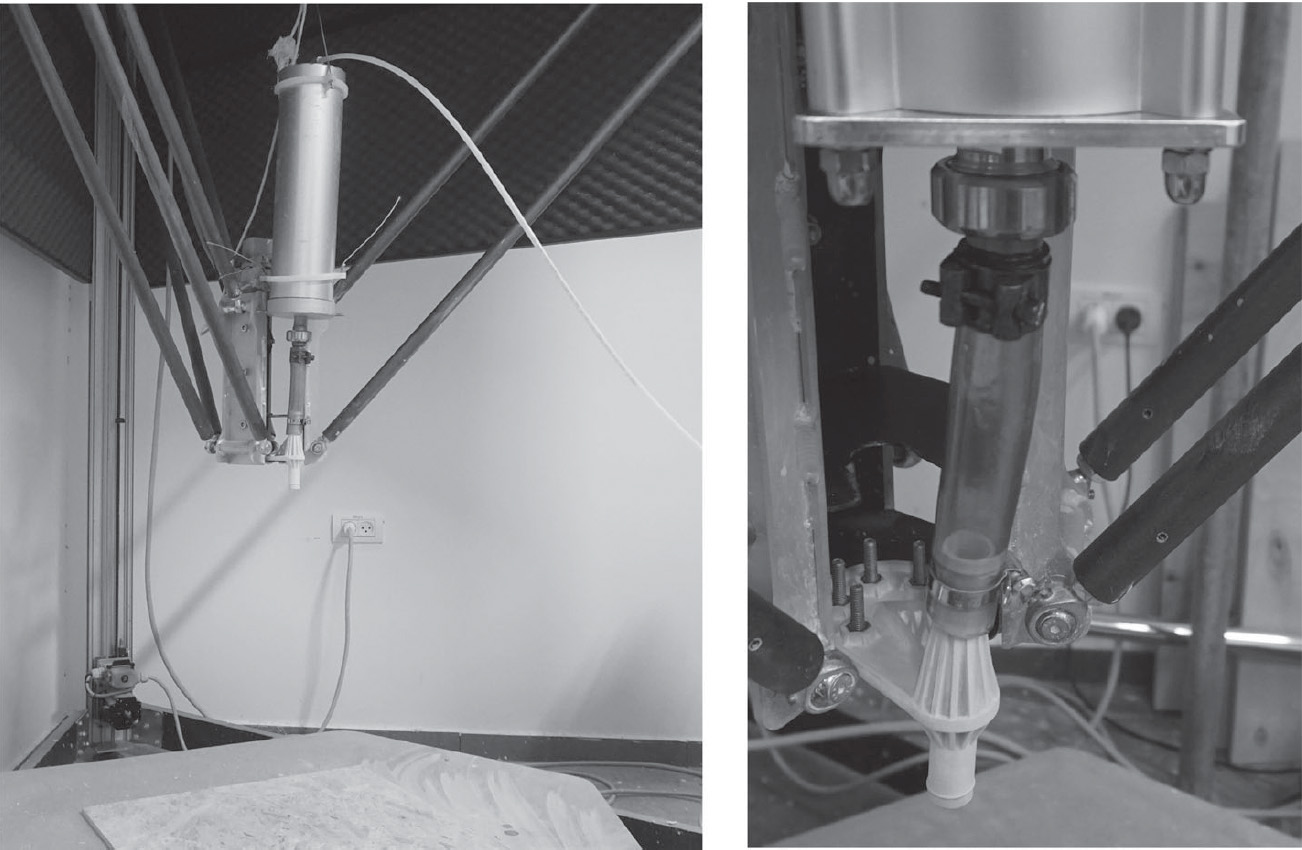

The lack of field-specific knowledge about earth construction in the architecture, engineering and construction (AEC) sector, the variety of soil that can be used and the labour-intensive nature of much earth construction have all hindered its advance into mainstream architecture. To overcome the barriers associated with traditional earth construction, novel approaches employ ‘ready-to-use’ mixtures for plasters or rammed earth, prefabricated elements, such as adobe bricks, rammed earth elements and earthen fibrous boards, and digital construction processes, such as additive manufacturing. These industrialized techniques are more controllable and produce high-quality outcomes, although they tend to eliminate the possibility of making changes during construction. Similarly, the convergence of additive manufacturing technology with earth-based materials could further advance implementation strategies for mass customization.

Thus, printability becomes a characteristic of an earthen mixture, reflecting its pumpability, extrudability and buildability

when in its fresh or ‘green’ state, and its compressive, flexural and tensile strength, as well as its high layer-interface strength, in its hardened state. These parameters are also affected by the mechanics, dimensions and set-up of the 3D-printing system.

Novel field measurements are required to obtain the rheological properties of fresh earthen materials in industrial application.

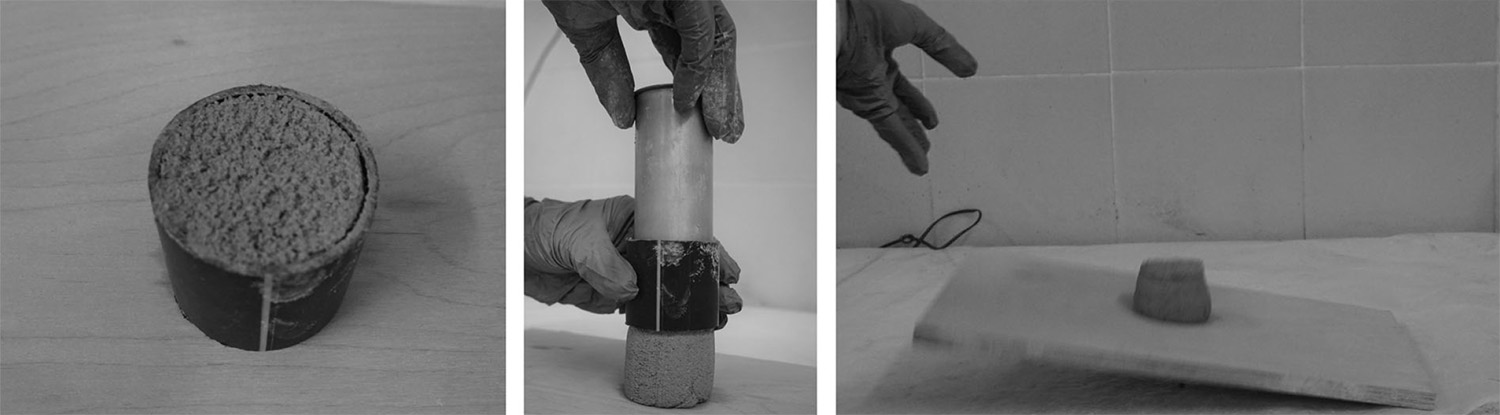

Hence, this research direction aims to clarify the composition of printable earthen material, such that it can be codified and provide additional support to academic and professional R&D innovation contexts. It proposes a field-oriented methodology, including three characterization tests to optimize a material’s printability

with regard to consistency and cohesiveness. The method and tools that were developed will enable designers and manufacturers to define, evaluate and adjust the printability characteristics of earthen mixtures for additive manufacturing.

Direction 3:

Is currently under development. We plan to share the results in a publication soon.

Funding:

3.Bio composite materials in design: developing 3D printing methods for fungal mycelium-based materials. Principal investigator. Israel Science Foundation (ISF). 600,000NIS (~169,000US$). 2019

Collaboration:

The project is performed in collaboration with Dr. Galit Agranati

Scientific publications that were published on this research:

Rückrich, S. Agranati, G., Grobman, Y.J. Earth-based additive manufacturing: A field-oriented methodology for evaluating material printability. Architectural Science Review. November 2022. DOI: 10.1080/00038628.2022.2154739